LUFTWAFFE RESOURCE CENTER > FIGHTERS/DESTROYERS > BF 109 > VARIANTS > PREVIOUS PAGE

Variants - Bf 109G - Gustav

The G-1, produced from February 1942, was the first production version of the G-series and the first production Bf 109 with a pressurized cockpit. It could be identified by the small, horn-shaped air intake for the cockpit compressor just above the supercharger intake, on the left upper cowling. In addition, the angled armour plate for the pilot's head was replaced by a vertical piece which sealed-off the rear of the side-hinged cockpit canopy. Small, triangular armour-glass panels were fitted into the upper corners of this armour, although there were aircraft in which the plate was solid steel. Silica gel capsules were placed in each pane of the windscreen and opening canopy to absorb any moisture which may have been trapped in the double glazing. The last 80 G-1s built were lightweight G-1/R2. In these GM-1 nitrous oxide 'boost' was used, and the pilot's back armour was removed, as were all fittings for the long-range drop tank. A few G-1 flown by I./JG 1 are known to have carried the underwing 20 mm MG 151/20 cannon gondolas.

Messerschmitt Bf 109G-1 with 20 mm MG 151/20 cannon in underwing gondolas.

[Source: Unknown]

–G-2/R2: a reconnaissance aircraft with GM-1 and camera equipment. The rack and internal fuel lines for carrying a 300 L (80 US gal) under-fuselage drop-tank were widely used on G-2s, as were the underwing 20 mm MG 151/20 cannon gondolas. Several G-2s were fitted with the ETC 500 bomb rack, capable of carrying one 250 kg (550 lb) bomb. The final G-2 production batches built by Erla and Messerschmitt Regensburg were equipped as tropical aircraft (often referred to as G-2 trop), equipped with a sand-filter on the front of the supercharger intake and two small, teardrop-shaped metal brackets on the left side of the fuselage, below the cockpit sill. These were used as mounts for specially designed sun umbrellas (called Sonderwerkzeug or Special tool), which were used to shade the cockpit. A total of 167 G-1s were built between February and June 1942, 1,586 G-2s between May 1942 and February 1943, and one further G-2 was built in Győr, Hungary, in 1943. Maximum speed of the G-2 was 537 km/h (334 mph) at sea level and 660 km/h (410 mph) at 7,000 m (22,970 ft) rated altitude with the initial reduced 1.3 atm rating. Performance of the G-1 was similar, but above rated altitude the GM-1 system it was equipped with could be used to provide an additional 350 horsepower. With his G-1/R2, pilot R. Klein achieved 660 km/h (420 mph) at 12,000 m (39,370 ft), and a ceiling of 13,800 m (45,275 ft). The following variants of the G-1 and G-2 were produced: • G-0 (Pre-production aircraft, powered by a DB 601E engine)

• G-1 (Pressurized fighter, powered by a DB 605A engine)

– G-1/R2 (Reconnaissance fighter)

– G-1/U2 (High-altitude fighter with GM-1)

• G-2 (Light fighter)

– G-2/R1 (Long-range Fighter-bomber or JaboRei, with 2 × 300 L underwing drop

tanks, 500 kg/1,100 lb bomb under fuselage, extended second tail wheel, only

prototype)

– G-2/R2 (Reconnaissance fighter)

– G-2 trop (Tropicalized fighter) Bf 109G-3 & G-4

In September 1942, the G-4 appeared; this version was identical to the G-2 in all respects, including performance, except for being fitted with the FuG 16 VHF radio set, which provided much clearer radio transmissions and had three-times the range of the earlier HF sets. Externally this could be recognised by the position of the fuselage antenna lead-in which was moved further aft to between frames seven and eight on the fuselage spine. Due to the steady weight increases of the 109, from the spring of 1943 larger 660 × 160 mm (26 × 6.3 in) mainwheels were introduced, replacing the previously used 650 × 150 mm (25.6 × 6 in) type. The undercarriage legs were altered so that the wheel's vertical axis was nearly upright rather than being parallel with the oleo leg. These changes resulted in the fitting of teardrop-shaped fairings to the upper wing surface above the wheel-wells to accommodate the upper part of the mainwheels. The larger wheels and fairings were often retrofitted to G-2s. In addition, a larger 350 × 135 mm (14 × 5 in) tailwheel replaced the original 290 × 110 mm (11 × 4 in) one; the larger tailwheel no longer fitted the recess, so the retraction mechanism was disconnected and the tailwheel fixed down. Up to July 1943, 1,242 G-4s were produced, with an additional four in Győr and WNF factories in the second half of 1943.[72] Between January and February 1943, 50 examples of a pressurized version, the G-3 were also produced; similar to the G-1 although it was equipped with the same FuG 16 VHF radio set as the G-4. The following variants of the G-3 and G-4 were produced: • G-3 (Pressurized fighter, as G-1 with FuG 16 VHF radio; 50 built)

• G-4 (Fighter)

– G-4/R2 (Reconnaissance fighter)

– G-4/R3 (Long-range recon fighter, with 2 × 300 L underwing droptanks)

– G-4 trop (Tropicalized fighter)

– G-4/U3 (Reconnaissance fighter)

– G-4y (Command fighter) Bf 109G-5 & G-6

In February 1943, the G-6 was introduced with the 13 mm MG 131s, replacing the smaller 7.92 mm MG 17 – externally this resulted in two sizeable Beule blisters over the gun breeches, reducing speed by 9 km/h (6 mph). Over 12,000 examples were built well into 1944 although contradictory factory and RLM records do not allow an exact tally. The G-5 with a pressurized cockpit was identical to the G-6. A total of 475 examples were built between May 1943 and August 1944. The G-5/AS was equipped with a DB 605AS engine for high-altitude missions. GM-1-boosted G-5 and G-6 variants received the additional designation of "/U2" and were clearly identifiable as they use a modified, aerodynamically cleaner, engine cowl without the usual blisters. The G-6/U4 variant was armed with a 30 mm MK 108 cannon firing through the propeller hub instead of the 20 mm MG 151/20. The G-6 was very often seen during 1943 fitted with assembly sets, used to carry bombs or a drop tank, for use as a night fighter, or to increase firepower by adding rockets or extra gondola-style, underwing gun pod mount ordnance. The following variants of the G-5 and G-6 were produced: • G-5 (Pressurized fighter)

– G-5/U2 (High-altitude fighter with GM-1 boost)

– G-5/U2/R2 (High-altitude reconnaissance fighter with GM-1 boost)

– G-5/AS (High-altitude fighter with DB 605AS engine)

– G-5y (Command fighter)

• G-6 (Light fighter)

– G-6/R2 (Reconnaissance fighter, with MW 50)

– G-6/R3 (Long-range recon fighter, with 2 × 300 L underwing droptanks)

– G-6 trop (Tropicalized fighter)

– G-6/U2 (Fitted with GM-1)

– G-6/U3 (Reconnaissance fighter)

– G-6/U4 (As G-6 but with 30 mm MK 108 Motorkanone engine cannon)

– G-6y (Command fighter)

– G-6/AS (High-altitude fighter with DB 605AS engine)

– G-6/ASy (High-altitude command fighter)

– G-6N (Night fighter, usually with Rüstsätze VI (two

underwing MG 151/20 cannons) and sometimes with FuG 350Z Naxos)

– G-6/U4 N (as G-6N but with 30 mm MK 108 engine cannon) One offensive weapons upgrade in 1943 for the Bf 109G — and also used for the Fw 190A — was one that mounted the Werfer-Granate 21 heavy calibre rocket weapon system with one launching tube under each wing panel. The rockets, fitted with a massive 40.8 kg (90 lbs) warhead, were aimed via the standard Revi reflector sights, and were spin-stabilized in flight. In emergency, the tubes could be jettisoned via a small explosive charge. Intended as a "stand-off" weapon, fired from a distance of 1,200 meters and outside the effective range of the formations defensive guns, it was employed against Allied bomber formations, the Wfr. Gr. 21 rocket was unofficially known as the BR 21 (Bordrakete 21 cm) for the Bf 109G-5, G-6 and G-14. The weapons system received the designation of Rüstsätze VII on the G-10.

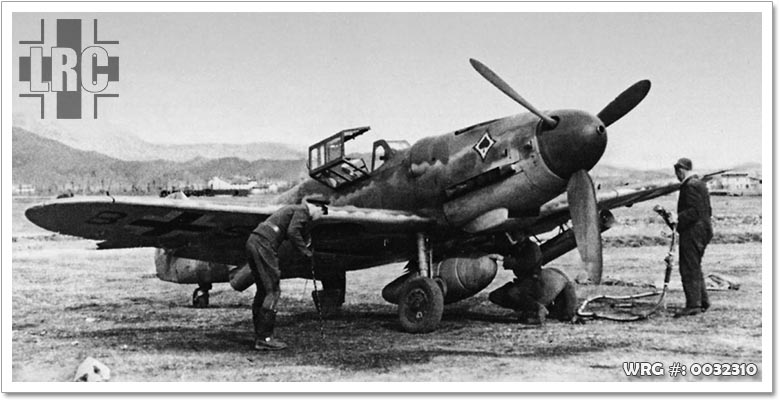

Bf 109G-6 with 300-liter drop tank and two Werfer-Granate 21 rocket launchers.

[Source: Unknown]

During the course of 1943, a number of improvements were gradually introduced. In an attempt to increase the pilot's field of view an armoured glass head-rest, the so-called Galland Panzer was developed, and subsequently began replacing the bulky armour plate in the spring of 1943. Towards the end of the year the clear-view Erla Haube canopy appeared, named after the Erla Maschinenwerk sub-contractor involved in building new examples, and upgrading older examples of the Bf 109. Often misnamed the "Galland Hood" in postwar Western aviation books and periodicals, it eventually replaced the older heavily framed two-piece canopy on the Bf 109G. The canopy structure was completely redesigned to incorporate a greater area of clear perspex; the welded framing was reduced to a minimum and there was no longer a fixed rear portion, with the entire structure aft of the windscreen being hinged to swing to starboard when opened. The Bf 109 G-10, AS-engined G-5s, G-6s and G-14s as well as the K-4 saw a refinement of the engine cowlings. The formerly separate, added-on Beule blisters which had earlier covered the spent shell-casing chutes of the synchronized fuselage-mount MG 131s were completely integrated into the upper cowling panels, vastly improving their streamlining and allowing them to be lengthened and enlarged to cover both the weapons and the engine bearers. Initial prototype versions were symmetrical, but as larger superchargers were fitted, the engines required modified upper engine bearers to clear the supercharger housing, and as a result the final shape of the new cowling was asymmetrical, being enlarged on the port side where the supercharger was mounted on the DB engine. There were also special streamlined panels fitted to the forward fuselage. These so-called agglomerations could be seen in several different patterns. Because of their aerodynamically more efficient form in a side-view of DB 605AS and D -powered Bf 109 Gs and Ks, the agglomerations were barely discernible compared with the conspicuous fairings they replaced. Late-production G-6, G-14, G-14/AS

Some versions of the G-6 and later Gs had a taller, wood-structure tail unit and redesigned rudder which improved stability at high speeds. The introduction of the WGr. 21 cm (8 in) under-wing mortar/rockets and the 30 mm MK 108 cannon increased firepower. Certain production batches of the Bf 109G were fitted with aileron Flettner tabs to decrease stick forces at high speeds. A radio-navigational method, the Y-Verführung (Y-Guidance) was introduced with the FuG 16ZY. Subsequent Bf 109G versions were essentially modified versions of the basic G-6 airframe. Early in 1944, new engines with larger superchargers for improved high-altitude performance (DB 605AS), or with MW-50 water injection for improved low/medium-altitude performance (DB 605AM), or these two features combined (DB 605ASM) were introduced into the Bf 109 G-6. Maximum speed of the G-5/G-6 was 530 km/h (320 mph) at sea level, 640 km/h (391 mph) at 6,600 m (21,650 ft)-rated altitude at 1.42 atm boost. The G-14 arrived in July 1944 at the invasion front over France. It represented an attempt to create a standard type, incorporating many changes which had been introduced during production of the G-6, and which led to a plethora of variants, plaguing decentralized mass production. The standardization attempt proved to be a failure, but overall the type offered improved combat performance, as MW 50 power boosting water injection (increasing output to 1,800 PS (1,775 hp, 1,324 kW), the clear-view Erla Haube was now standard installation. Top speed was 568 km/h (353 mph) at sea level, and 665 km/h (413 mph) at 5 km (16,400 ft) altitude. A high-altitude fighter, designated G-14/AS was also produced with the DB 605ASM high-altitude engine. The ASM engine was built with a larger capacity supercharger, and had a higher rated altitude, and correspondingly the top speed of the G-14/AS was 560 km/h (348 mph) at sea level, and 680 km/h (422 mph) at 7.5 km (24,600 ft) altitude. There was increasing tendency to use plywood on some less vital parts e.g. on a taller tailfin/rudder unit, pilot seat or instrument panel. A cautious estimate based on the available records suggest that about 5,500 G-14s and G-14/AS were built. The following variants of the G-14 were produced: • G-14 (Standardized late-production G-6; DB 605AM engine, MW 50 boost)

– G-14/AS (High-altitude fighter with DB 605ASM engine, MW 50 boost)

– G-14/ASy (High-altitude command fighter)

– G-14y (command fighter)

– G-14/U4 (As G-14, but with 30 mm MK 108 engine cannon) Bf 109G-8

The G-8 was a dedicated reconnaissance version based on the G-6. The G-8 often had only the Motorkanone engine cannon or the cowling machine guns installed, and there were several subversions for short- or long-range reconnaissance missions with a wide variety of cameras and radios available for use. Bf 109G-10

Referred to as the "bastard aircraft of the Erla factory" in the Luftwaffe's Aircraft Variants Book of December 1944, the G-10 was a Bf 109 G airframe combined with the new DB 605 D-2 engine, created to maintain production levels with minimal disruption of the assembly lines until production of K-series airframes would reach sufficient levels. Despite what the designation would suggest, it appeared in service after the G-14 in November 1944, largely replacing previous G-series aircraft on the production lines of Erla, WNF and Messerschmitt Regensburg factories. Contrary to popular belief the G-10 were not rebuilt older airframes but new production. Early production G-10 may have had two data plates (usually with G-14 stamped onto it) as these airframes were originally intended to be used for G-14 assembly but were diverted to G-10 assembly. The most recognizable external change was the use of the three-panel Erla-Haube clear-view canopy, which filled the entire canopy length behind the four-panel windscreen unit, which eliminated the older, rear fixed canopy section. Internal changes included inheriting the new 2,000 W generator and the DB 605 D-2 engine of the 109K. Apart from the standardised streamlined engine cowlings, G-10s with the DB605 D-2 were equipped as standard with the MW-50 booster system (DB 605DM, later 605DB) and had a larger Fo 987 oil cooler housed in a deeper fairing. Also, because of the engine's enlarged crankcase and the oil return lines which ran in front of it, these G-10s had small blister fairings incorporated into the lower engine cowlings, forward of and below the exhaust stacks. The following variants of the G-10 were produced: • G-10 (Light fighter with DB605DM or DB/DC engine)

– G-10/R2 (Reconnaissance fighter)

– G-10/R6 (Bad-weather fighter with PKS 12 autopilot)

– G-10/U4 (As G-10 but with 30 mm MK 108 engine cannon) Approximately 2,600 G-10s were produced from October 1944 until the war's end. Bf 109G-12

The Bf 109 G-12 was a two-seat trainer version of the Bf 109. This was a conversion of "war-weary" or rebuilt G-4 and G-6 airframes; the space needed for the second cockpit was gained by reducing the internal fuel capacity to only 240 L (60 US gal) meaning that the 300 L (80 US gal) drop tank was employed as standard equipment. This version was rarely armed with anything more than one or two cowling machine guns. The rear cockpit canopy was bowed out to give the instructor, who sat behind the student pilot in an armoured seat, a clearer view. The rear cockpit was also equipped with a basic instrument panel and all flight controls. Bf 109G subtypes and variants

The base subtypes could be equipped with Rüstsätze add-on standard field kits; in practice this meant hanging on some sort of additional equipment like droptanks, bombs or cannons to standard attachment points, present on all production aircraft. Aircraft could be modified in the factory with Umrüst-bausatz (Umbau) conversion kits or by adding extra equipment, called Rüstzustand, to convert standard airframes for special roles, a reconnaissance or bad-weather fighter, for example. Unlike the Rüstsätze field-kits, these modifications were permanent. The Rüstsätze kits were labelled with the letter "R" and a Roman numeral. Rüstsätze kits did not alter the aircraft type so a Bf 109 G-6 with Rüstsätze II (50 kg/110 lb bombs) remained a Bf 109 G-6 and not G-6/R2, which was a reconnaissance fighter with MW 50, as suggested by most publications. The Umrüst-Bausatz, Umbau or Rüstzustand were identified with either an "/R" or "/U" suffix and an Arabic number, e.g. Bf 109 G-10/U4. Common Rüstsätze kits for Bf 109G: • R I (ETC 501/IX b bomb rack under the fuselage, fusing equipment for an SC 250

or SD 250 type 250 kg (550 lb) bomb)

• R II (ETC 50/VIII d bomb rack under the fuselage, fusing equipment, for

four SC 50 type 50 kg (110 lb) bombs)

• R III (Schloß 503A-1 rack for one fuselage drop tank (300 L/80 US gal))

• R IV (two 30 mm Rheinmetall-Borsig MK 108 underwing gunpods)

• R VI (two 20 mm Mauser MG 151/20 underwing gunpods with 135 rpg)

• R VII (Peilrufanlage) Common Umrüst-Bausatz (Umbau) numbers: U1 (Messerschmitt P6 reversible-pitch propeller to be used as air brake,

only prototypes)

U2 (GM-1 boost, during 1944 several hundred converted to MW-50 boost)

U3 (Reconnaissance conversion, in autumn 1943 G-6/U3 adopted as G-8

production variant)

U4 (30 mm MK 108 Motorkanone engine-mounted cannon)

Sources:

Wikipedia

LUFTWAFFE RESOURCE CENTER > FIGHTERS/DESTROYERS > BF 109 > VARIANTS > PREVIOUS PAGE